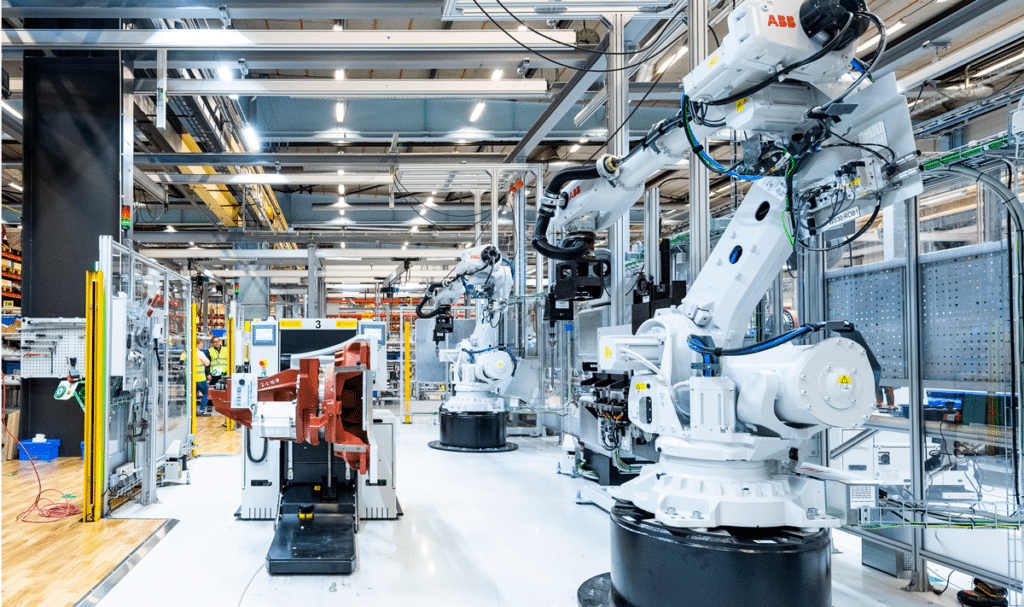

Emergency maintenance

Fast and reliable support to get your production back on track

Our helpdesk provides immediate assistance from our experienced service engineers, who quickly diagnose and resolve issues with your mechanical equipment.

If your system allows, we remotely connect to your equipment to analyze error logs, examine input/output status, and troubleshoot the issue—ensuring a swift resolution to restart production.

For older equipment or systems without remote access, we offer onsite call-out services to resolve the problem directly at your facility. Response time depends on your location and specific requirements.

Preventive maintenance

Minimize downtime with proactive service

Prevent unexpected breakdowns and production stoppages with preventive maintenance from Elektroautomatik Service—a smart and proactive approach to industrial service.

Depending on your operations, we offer:

🔹Scheduled maintenance – Regularly planned servicing at predetermined intervals.

🔹Condition-based maintenance – Maintenance based on real-time equipment performance and wear indicators.

Improvement maintenance

Maximize reliability and efficiency in production

To achieve maximum reliability in your production, we offer improvement maintenance—an advanced strategy for optimizing performance and extending equipment lifespan.

This includes:

🔹Service procedure analysis – Identifying areas for efficiency gains.

🔹Fault analysis with TPM and Lean tools – Finding root causes and implementing long-term solutions.

🔹Customized action plan – A structured roadmap, developed together with you, based on your company’s goals, vision, and policies.

Additionally, we offer:

🔹 Spare parts management – Ensuring you always have critical components available.

🔹 Operator maintenance development – Training and support to enhance internal maintenance capabilities.